To protect this precious natural resource, a Management Conference for the Long Island Sound Study developed a comprehensive plan to protect and improve the health of the Sound. It concluded that a condition called hypoxia, which is low dissolved oxygen, was afflicting a substantial portion of the Sound's marine habitat in late summer. In turn, New York State Department of Environmental Conservation (NYSDEC) imposed limits to reduce nitrogen discharged from the 12 municipal treatment plants located on the north shore of Long Island.

The Oyster Bay Sewer District (OBSD) discharges treated effluent to Oyster Bay Harbor, which is an embayment to Long Island Sound. NYSDEC issued a revised permit that required the OBSD to reduce nitrogen discharged to Oyster Bay from the treatment plant by 63.8 percent in three 5-year increments by August 2014.

H2M provided planning, design, and construction related services under the direction of Project Manager Steven C. Hearl, P.E. The OBSD Commissioners agreed with H2M's recommendation that it would be more beneficial to construct the nitrogen removal facilities to meet the ultimate total nitrogen reduction goal rather than a phased program to achieve each interim limit. This decision resulted in a quicker improvement to water quality.

The nitrogen baseline load discharged by OBSD was 220 pounds per day. At the permit flow limit of 1.8 MGD, the effluent total nitrogen concentration needed to be less than 5.3 mg/l. to meet the maximum 80 pounds per day limit by August 1, 2014. H2M recommended the Sequencing Batch Reactor (SBR) process since it would achieve a design effluent total nitrogen concentration of only 4 mg/l.

The OBSD facility is located on a waterfront parcel with limited area. To provide space, the design required the removal of the existing trickling filters so that the SBR could be constructed. The District met permit limits throughout construction by modifying operations of existing facilities.

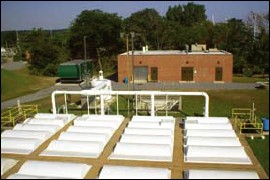

A new 40-foot by 60-foot single story building on a pile foundation was constructed to house the motor control centers, SBR and sludge holding tank blowers, and sludge belt thickener. A new diesel fueled standby generator was installed in a sound attenuating enclosure to allow for the plant to operate during power outages.

To protect tidal wetlands that were within 60-feet of the new tanks, positive site drainage facilities, gravel roadways and porous roadways were installed to minimize runoff. The four existing primary clarifiers were reutilized as pre-equalization basins to reduce influent hydraulic and mass loading variability.

The innovative SBR process was put online in December 2005 and the 12-month rolling average for effluent total nitrogen is in the range of 50 to 70 pounds per day. H2M's design has achieved the 2014 requirements approximately eight years ahead of schedule. That's good news for Oyster Bay Harbor, and the future of our beautiful Long Island Sound.

SBR/Sludge Holding Tank. Harbor in background. |  SBR in operation. |

Covered pre-equalization basins and odor control. Blower/thickener/control building in background. |  Blower Room. |